PRODUCT RESEARCH AND DEVELOPMENT

20+ YEARS OF BRINGING NEW HEALTH PRODUCTS TO MARKET

Island Abbey Nutritionals™ maintains a highly skilled and experienced product development team working diligently to develop new products, improve lead time, and streamline the R&D process. Our rich product pipeline and extensive in-house R&D capacity supports continuous product innovations and commercialization.

Our delivery platforms can be used to deliver any natural health product, dietary supplement, or other therapeutic ingredient into the body naturally. Our research and development over the past 20 years has involved testing all-natural compounds and ingredients (VMS, herbal, botanical, etc.).

From concept to launch, our NPI (New Product Introduction) is complexity-based and customized to your needs to efficiently complete the full NPI cycle. Variables will include ingredients used, the manufacturing process, and similarity to current products.

Development Process Overview

Project Scope and Client Review

Initial FORMULATION DEVELOPMENT

RECIPE PILOT AND TESTING

CUSTOMER REVIEW AND QUALITY ASSURANCE

RECIPE FINALIZATION AND APPROVAL

INGREDIENT AND RAW MATERIAL PURCHASING

DESIGN AND ARTWORK DEVELOPMENT

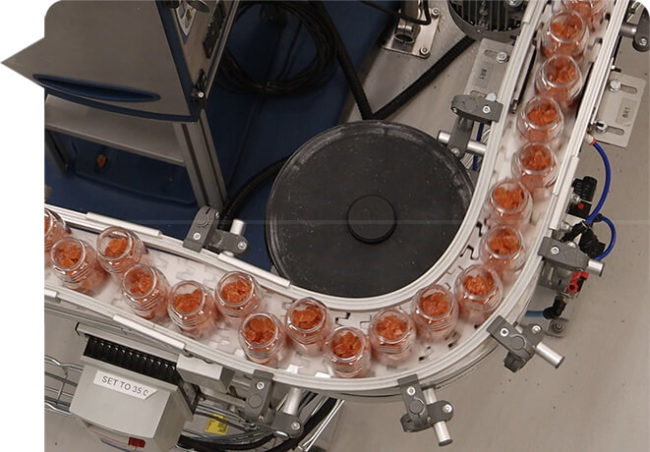

BULK PRODUCTION AND PACKAGING